Waste Management Company | Scrap Recycling Services

- Open Hours: Mon-Sat 10:30 am-7:00 pm

- Email: info@spasrecycling.com

- Address: T-15 Pinnacle Business Park Andheri East

- TollFree : 18002122130

Cable Recycling Company in India

Cable Scrap Recycling Company

Cable Recycling Company in Mumbai, India

Cable recycling business Spas Recycling Pvt Ltd govt. authorized cable recycling company is renowned for its excellent performance, affordable production costs, and minimal metal loss. With our extensive array of tools and machines, we can create systems for the recycling of cables in accordance with specifications and manufacturing procedures, enabling us to provide you with a productive and economical solution.

Our machines and systems for size reduction and separation are designed using ambient mechanical techniques; no melting or chemical treatment is needed. Depending on your needs, we provide both regular and specialized cable recycling options. When customizing solutions for up to 10,000 kg input/production hour, the standard solutions, with capacities ranging from 300 to 5000 kg, are usually the first place to start. Moreover, we provide cable strippers and shears for smaller capacities or to enhance other cable recycling methods

For Services

- +91 8689-899-899

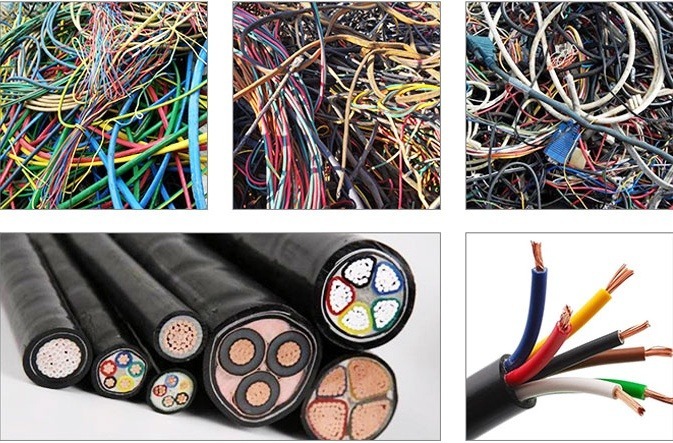

Scrap Cable We Buy

We collect, recycle & disposal all types of Cable Wire Scrap Materials

- Insulated Copper Wire Scrap

- Bare Copper Wire Scrap

- Aluminum Wire Scrap

- Stranded Wire Scrap

- Mixed Wire Scrap

- Low-Grade Cable Wire Scrap

- High-Voltage Cable Scrap

- Miscellaneous Cables & Wires

Cable Scrap Recycling Process

Our Cable Recycling Process

- Collection and segregation

Scrap yards and specialized recycling businesses are primarily responsible for collecting cable scrap from a variety of sources, including electro-waste, electrical installation dismantling, telecom and power network decommissioning, renovation, and demolition.

- Insulation removal

After the cables are gathered, the recycling procedure typically begins with the insulation being removed. Rubber, PVC, and polyethylene are a few of the materials that can be used to make insulation. The insulation and cable core are separated by mechanical procedures.

- Shredding

Next, the cables are cut into smaller bits. Shredders and other mechanical devices can be used to cut cables into smaller pieces, This reduction in size facilitates easier handling and enhances the efficiency of subsequent separation processes in recycling procedures

- Metal separation

The cables go through metal separation procedures following their shredding. The waste is run through machinery designed to separate the various metals—such as copper, aluminum, or steel—based on their unique weights, densities, or magnetic properties.

- Dust and plastic cleaning

A cleaning procedure for plastics and dust that may include metal particles must be done in order to recover 100% of the valuable metals from the cables. Among other things, induction separators are employed for this purpose

- Purification of raw materials

Plastics are utilized as intermediary goods in the creation of products, while metals, which are the primary raw materials gained from the separation process, are sold to smelters and foundries. An essential part of any electrical or electronic equipment are cables.

- Processing of raw materials

We break out the conductive metal portion of the scrap cable from the plastic portion by crushing it with our cable recycling devices. The material is separated into fine-grain metals and plastic granules. Our cable stripper processing can handle lead or steel armoring seen on power lines.

About Cable Recycling

About Cable Wire Scrap

An essential part of any electrical or electronic equipment are cables. The majority of cables include an inner conductive metal section covered in an insulator, typically made of PVC or plastic.

Copper and aluminum, which are commonly used to make metal parts, may be recycled indefinitely without losing any of their quality. Paper, rubber, or plastic are used as insulating materials.

We break out the conductive metal portion of the scrap cable from the plastic portion by crushing it with our cable recycling devices. The material is separated into fine-grain metals and plastic granules. Our cable stripper processing can handle lead or steel armoring seen on power lines. Recycling has years of experience in providing full processing lines for various kinds of wire and cable debris. The separation, pre-shredding, granulating, sorting, and sorting technologies used allow for the recovery of individual metal fractions with about 100% purity.

Benefits of Cable Scrap Recycling

Benefits of Electric Cable Recycling

Preservation of resources

We can lessen the need for extracting and processing new metals by recycling electric cables, which contributes to the preservation of natural resources.

Waste reduction

Recycling electric cables helps lessen the quantity of waste that is disposed of in landfills, which can lessen the influence these facilities have on the environment.

Energy conservation

Recycling metals lowers greenhouse gas emissions and energy consumption since it uses less energy than mining and processing new metals.

Cost savings

Reusing electric cables can save money for both producers and users because it might be less expensive than building new wires from the ground up.

All India Cable/Wire Scrap Collection, Management & Handling Services